Application:

KLEANOIL® VLP Series Lubricating Oil Purification System is designed for conditioning industrial lube oils, such as gear oil,mechanical oil, coolant oil, bearing oil, etc, so as to maintain oil quality, and extend service life.

Feature:

• Designed for lubricating oil filtration

• Various flow rate models available

• Both water and particulate removal

• Filter fineness customizable according to the oil to be treated

• Moisture removal down to 50 ppm or less

• Water oil separation coalescence technology

• Automatic oil feed & discharge balancing

• Interlocked preventive mechanism

• Low watt density heating system

• Intelligent foam control

Advantage:

Lubricating oil works in harsh environment, and often get contaminated with liquid, gas, scraps and other particulate impurities. The VLP lube oil purifier is design to expand the service life of oil and the operating efficiency of your equipment. Regular oil processing also enhances oil quality and restores the oil’s cleanness.

Structure:

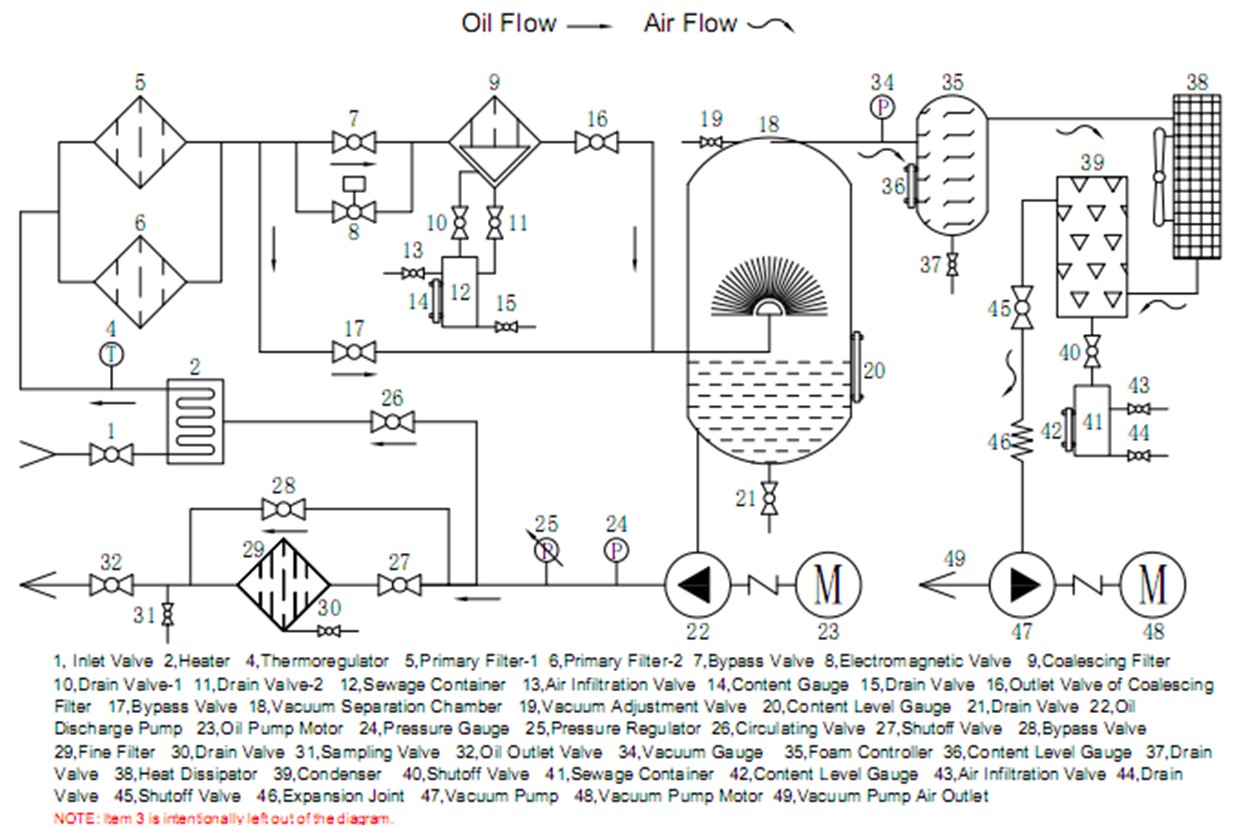

Flowchart:

Technical Specification:

Item | Unit | VLP-10 | VLP-20 | VLP-30 | VLP-50 | VLP-100 | VLP-150 | VLP-200 | VLP-300 |

Flow Rate | L/min | 10 | 20 | 30 | 50 | 100 | 150 | 200 | 300 |

Vacuum Degree | MPa | -0.06 ~ -0.095 | |||||||

Working Pressure | MPa | ≤0.5 | |||||||

Temperature | ℃ | 20 ~ 80 | |||||||

Water Content | PPM | ≤50 | |||||||

Cleanness | NAS | ≤6 grade | |||||||

Power Supply | Any Voltage Hertz Phase as required | ||||||||

Working Noise | dB(A) | ≤75 | ≤75 | ≤75 | ≤78 | ≤78 | ≤78 | ≤80 | ≤82 |

Heating Power | KW | 19 | 24 | 30 | 40 | 60 | 90 | 120 | 150 |

Total power | KW | 21 | 26.5 | 33 | 44 | 65 | 96 | 127 | 159 |

Inlet/outlet caliber | mm | 25 | 25 | 25 | 32 | 42 | 50 | 50 | 60 |

Weight | Kg | 450 | 550 | 650 | 800 | 1100 | 1300 | 1500 | 1700 |

Note: The technical data are for reference only. We reserve the right to make changes in the course of technical development of the product.